Restaurant table tops are where design, durability, and service collide. This buyer’s guide explains materials, finishes, sizing, mounts, and care so you can specify with confidence.

When it comes to the perfect dining experience, few elements matter more than the restaurant tables. Restaurant tabletops set the tone for your space. They dictate how long furniture will last, and can even impact how comfortable and safe guests feel. Choosing the right materials for restaurant table tops is about much more than solid wood vs laminate. It’s about durability, aesthetics, maintenance, and long-term return on investment.

At TimeWorn, we’ve spent over 15 years manufacturing custom restaurant tables that withstand the daily demands of high-traffic dining. In this guide, we’ll break down everything you need to know before investing in restaurant tabletops in 2025.

Why Restaurant Table Tops Matter

Your tables are one of the very first things guests notice when they sit down. The tables play a bigger role than most owners realize. They set the tone for your brand. Whether that’s modern and refined, rustic and welcoming, or high-energy and communal. The tables immediately signal the level of care you put into your dining experience. The wrong table tops can wear out quickly, forcing you into costly replacements, or worse, they can look cheap and clash with your restaurant’s design. Poor sizing or layout decisions can also create ADA compliance problems and make guests feel cramped or uncomfortable. Well-designed tables, by contrast, create an inviting atmosphere, maximize your seating capacity, and make every diner feel more at ease. They’re not just furniture, they’re functional design tools that directly impact how long guests stay, how comfortable they are, and how they remember their visit.

Key reasons to prioritize your tabletops:

- First impressions: Tables set the aesthetic tone of the dining room.

- Longevity: Durable tabletops reduce replacement cycles.

- Compliance & safety: Proper sizing and spacing ensures ADA accessibility and guest comfort.

- Return on investment: Higher-quality tables last longer, saving money over time.

Standard Sizes & Seating Capacity

Restaurant table tops are produced in a wide range of standard sizes. Choosing the right dimensions impacts how many guests you can seat. The dimensions also determine how comfortable the customers feel. To make this easier, we’ve created two detailed drawings that cover 32 of the most common table sizes. This ncludes rounds and drop-leaf options.

The first drawing provides seating recommendations for bar and quick-service restaurants, where layouts typically allow about 18″ per guest. The second drawing is designed for casual and fine dining establishments. With an understanding that 24″ per guest is the standard for comfort and service. Both drawings clearly indicate how many guests we recommend seating at each restaurant table top size. This gives you a quick and accurate reference for seat planning.

At a Glance

- ◆ Keep 36″ clear in main paths.

- ◆ Mix two-tops and communal for flexibility.

- ◆ Need help? Contact us or see the FAQ.

Best Wood Species for Wood Restaurant Tops

Not all wood is created equal, especially in a commercial dining setting. Below are the most popular species we source at TimeWorn, paired with thoughtful craftsmanship techniques that elevate both durability and aesthetics:

- Walnut: A premium choice with deep, rich tones and smooth grain. Ideal for upscale venues. We finish it with our two-part acrylic polyurethane matte system to enhance chemical and heat resistance.

- White Oak: Known for its timeless beauty and exceptional wear resistance. We primarily use quarter-sawn white oak for its enhanced stability and durability.

- Maple: Affordable and clean in appearance. Popular in modern designs. Our quick-ship maple tabletops showcase its lighter coloring and smooth texture with ease.

- Ash: Strong with a straight grain and classic appeal. A great value option for high-use areas.

- Reclaimed Oak or Pine (Barn Wood): Offers rustic charm, unique character, and environmental benefits. Our reclaimed materials are kiln-dried to below 5% moisture and fully lead-free.

Pro Tip

Mix species by zone, walnut for dining areas and reclaimed oak for bars. This balances aesthetics and budget while maintaining visual continuity.

Types of Table Tops

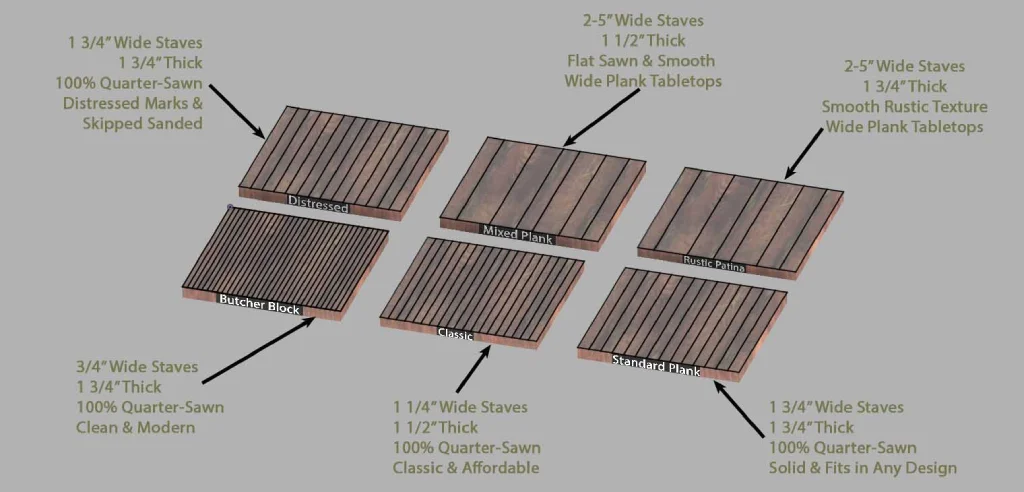

When it comes to restaurant furniture, the construction method and surface texture of your tables matter just as much as the wood species. At TimeWorn, we classify our solid wood table tops by how they’re built, the width of the staves, and the level of texture each style brings to your space:

- Butcher Block – Built from 100% quarter-sawn wood with ~¾″ staves for a clean, uniform look. Tight, consistent grain delivers exceptional strength and stability, making this style a dependable choice for high-traffic restaurants.

- Classic – A TimeWorn signature using 100% quarter-sawn wood with slightly wider 1¼″ staves. Visible ray flecking and subtle “tiger striping” create a timeless aesthetic that blends elegance with long-term performance.

- Distressed – 1½–2″ staves feature intentional character, saw kerfs, knots, and chatter, adding warmth and history. A favorite for breweries, pubs, and rustic concepts, it offers a lived-in feel while staying smooth and service-ready.

- Mixed Plank – Wider 3–5″ staves create a bold, casual look. Natural heartwood–sapwood variation is often showcased, so each top feels distinct, ideal for relaxed spaces that still want visual interest.

- Rustic Patina – A TimeWorn original coined 15+ years ago. Select rough-sawn textures are intentionally preserved for handcrafted authenticity that embraces imperfection while maintaining a smooth, usable surface.

- Standard Plank – Quarter-sawn construction with 1½–2″ staves. Introduced by TimeWorn over 15 years ago, it remains a reliable, traditional option that balances familiar aesthetics with proven durability in daily service.

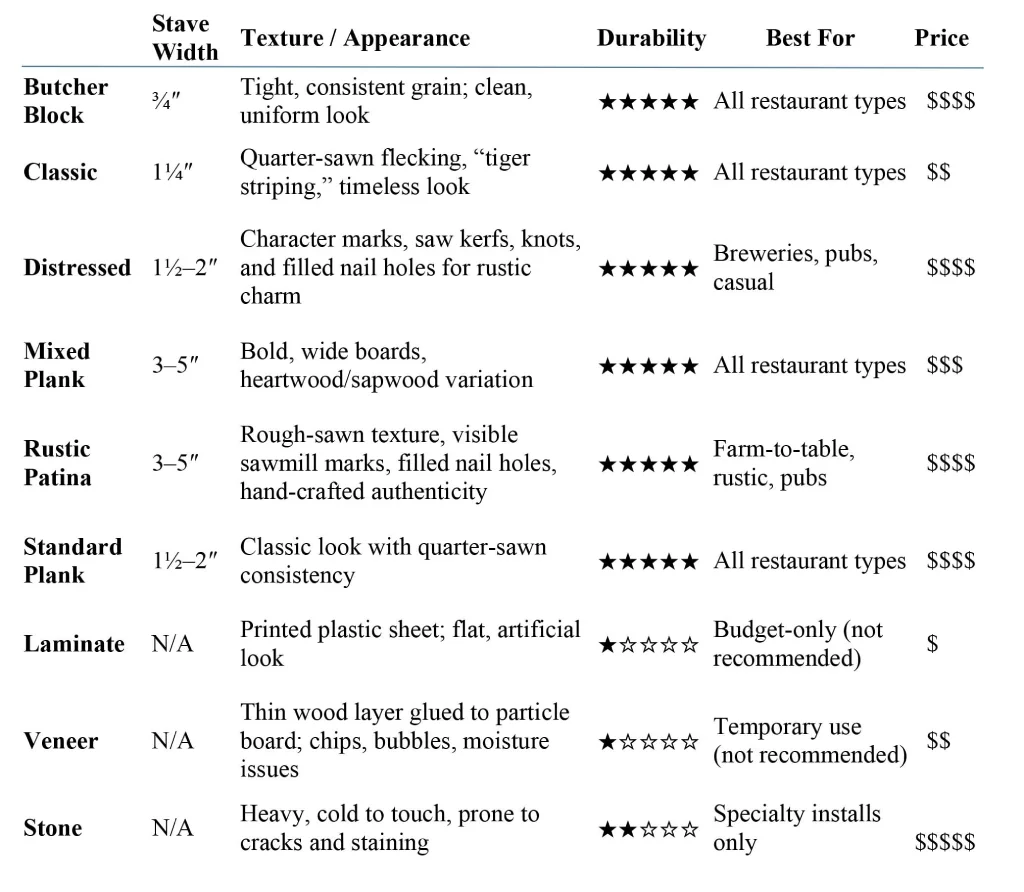

Other Materials (and Why We Don’t Recommend Them)

- Laminate – A thin sheet of plastic bonded to particle board. It scratches, peels, and looks cheap.

- Veneer – A thin wood layer glued to particle board. Susceptible to bubbling, chipping, and failure under moisture.

- Stone – Heavy, cold to the touch, and prone to cracking in busy restaurant settings.

At the end of the day, solid wood remains the gold standard. It delivers the warmth, durability, and premium aesthetics that operators, designers, and guests all notice, and when properly finished, it easily outlasts cheaper substitutes. Here is a comparison table including all your restaurant table top options, not just wood:

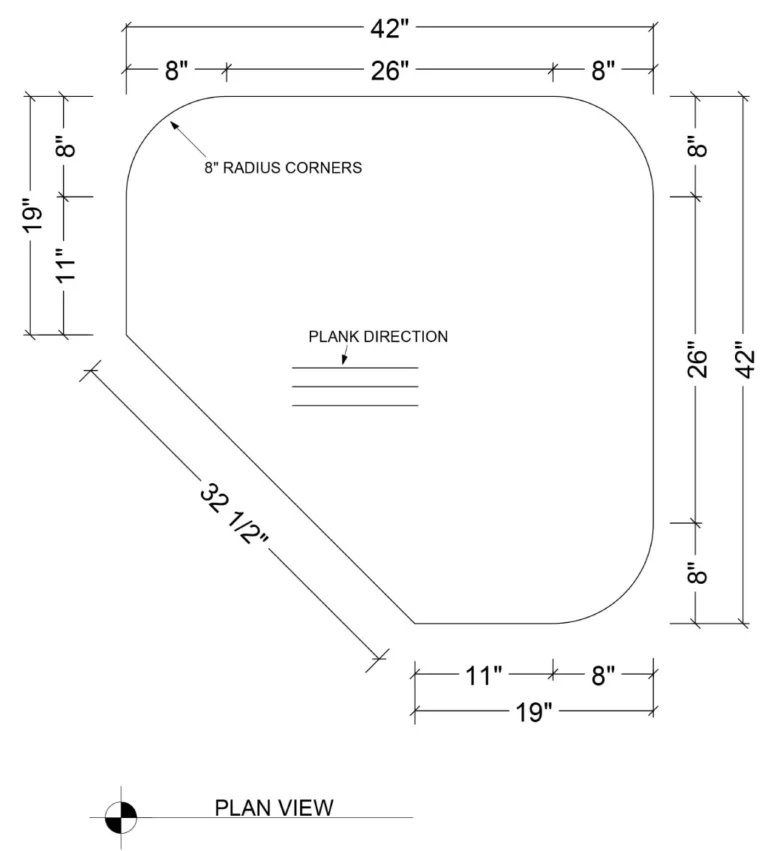

Custom Shapes & Specialty Table Tops

Not every restaurant table is a simple rectangle. In many rooms, custom shapes work better. Moreover, custom designs solve functional challenges and enhance the dining experience. As a result, the right shape can improve traffic flow, and it can also maximize capacity. Finally, it creates greater comfort for both guests and staff.

Booth Tables

Booths are among the most space-efficient and comfortable seating options in restaurants. Therefore, to ensure a tabletop that fits perfectly, we need precise measurements directly from your booth manufacturer, including:

- Inside booth width and depth (measured cushion-to-cushion).

- Clearance for table overhang (typically 1½–2″ per side).

- Any radius or angle details on the booth corners.

Accurate dimensions ensure the table top nests neatly, giving guests a seamless dining experience without wasted space or awkward gaps.

B ar Tops

ar Tops

Restaurant Bar tops bring unique requirements because they’re not only functional but often the centerpiece of your establishment. For a flawless build, we’ll need:

- Overall bar length (wall-to-wall or corner-to-corner).

- Bar depth (front edge to wall or drink rail).

- Cutout details (sinks, beer taps, POS stations, ADA drop-downs).

Connection details if the bar will exceed 14′ and need hardware for seamless joins.

The more precise the drawings, the better we can ensure your bar top is manufactured to spec, assembled quickly on-site, and built for long-term durability.

Design Insight

Plan bar ergonomics early. Confirm guest overhang targets, drink-rail depth, and ADA drop-down locations. For spans over 14′, specify joiner hardware and grain direction. Seal all cutouts, note left or right orientation on drawings, and include a drip groove under wet edges for cleaner service.

Rounds

Round tables create a sense of intimacy and conversation that rectangular tables can’t match. However, they require more floor space per seat, which can reduce overall capacity in high-volume restaurants. Use them strategically in corners, private dining rooms, or spaces where creating a social vibe matters more than maximizing cover count.

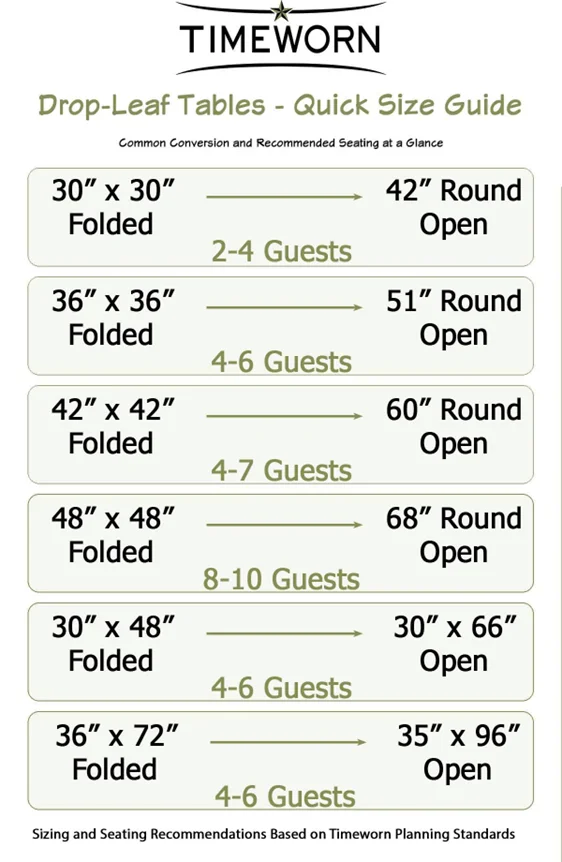

Drop-Leaf Tables

offer unmatched versatility, ideal for restaurants that need to adapt seating configurations on the fly. At TimeWorn, our drop-leaf tables are more than space-savers; they’re crafted from premium solid wood and designed to enhance both form and function.

Space-Savvy Design for Any Layout

Our most popular variant is the square-to-round drop-leaf table, which can transform a 36″×36″ square into a 51″ round, comfortably seating 4 to 6 guests. Larger options like a 48″ square converting to 68″ round require four legs for rock-solid support. These designs are perfect when you need to quickly accommodate larger parties without rearranging your floor plan.

Stylish Yet Sturdy Construction

Crafted using the same solid woods as our tabletops, these tables effortlessly blend with your design aesthetic while offering long-lasting durability. Every drop leaf is cut with unparalleled accuracy on our CNC, and the 80+ required screws are flawlessly pre-drilled by the CNC as well, ensuring each table is built to absolute perfection and precision. This meticulous process guarantees flawless movement when folding the tables up or down. Hinges and hardware in our drop-leaf models are always commercial-grade metal, built to handle frequent use and movement.

Customizable by Style and Size

Choose from a variety of shapes, square-to-round, extending rectangles, or custom designs to fit your space. Whether you’re outfitting a café, banquet room, or event space, our drop-leaf tables adapt beautifully to your needs.

Perfect For:

- Restaurants with varying traffic levels, expand for busier times, collapse for quieter hours, such as hotels & the hospitality industry.

- Multipurpose areas and catering zones that require both openness and seating.

- Limited-footprint venues like cafés or patios where flexibility is essential.

Design + Operational Considerations

- Extended leaf options may require additional legs for balance and safety.

- Train staff to use and lock leaves first, this avoids wobbling or injury during service.

- Include measurements for both deployed and folded states in your layout plans for clearance, circulation, and cleaning.

A Blend of Elegance and Practicality

Drop-leaf tables are an elegant solution for modern restaurants, they balance flexibility, efficiency, and visual appeal seamlessly. As we say at TimeWorn, they perfectly combine “the versatility of modern design with the quality of timeless craftsmanship.”

Featured Answer

Why choose drop-leaf tables for restaurants?

Drop-leaf tables deliver unmatched flexibility for changing floor layouts. They save space during off-peak hours, expand seating fast when needed, and maintain a seamless design that complements solid wood tabletops. For operators, it’s the perfect mix of versatility, durability, and visual appeal.

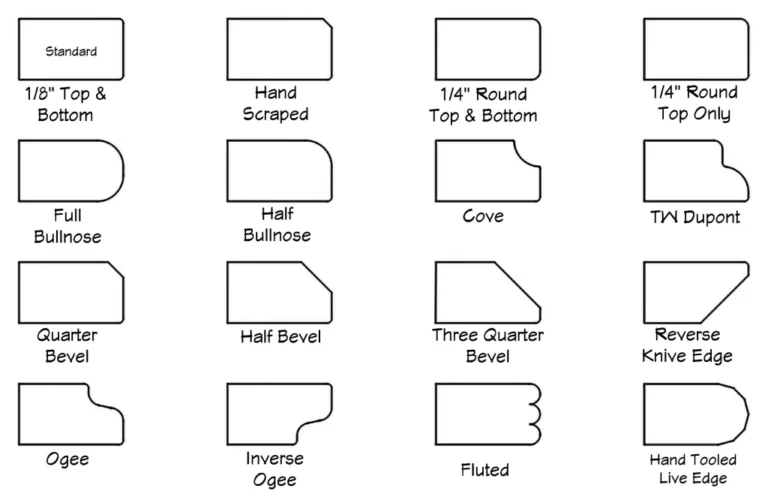

Restaurant Table Top Edge Profiles & Customization Options

Edge design is often overlooked but directly impacts both comfort and branding.

- Standard: Modern and clean.

- ¼” Round Over: Softer, safer, and comfortable for arms.

- Beveled Edge: Adds sophistication and visual flair.

- Reverse Knife Edge: Extremely popular and modern.

- Full Bullnose: Very unique, stands out as the softest option.

- Custom CNC Profiles: Logos, patterns, or unique curves add branding value.

Architects and designers increasingly request, custom tabletop edges, CNC-cut logos or brand marks on restaurant tops as a subtle way to elevate the guest experience.

Finish Systems That Survive Daily Cleaning

Choosing the right finish for your table style is even more crucial than the wood itself, especially in the restaurant world where surfaces endure constant cleaning, heat, moisture, and chemical exposure. At TimeWorn, we don’t just build beautiful tables, we engineer them to stay functional and safe for your staff and guests.

Why the finish matters on wood tables

Sticky, tacky surfaces are more than just annoying; studies and customer feedback show they can impact customer comfort, cleaning routines, and even perception of hygiene. When cleaners and sanitizers degrade the finish, it breaks down, becomes sticky, and looks worn out, potentially harming guest experience and safety. Our goal is to retain that smooth, clean feel day in and day out, so your tables look and function perfectly even under intense use.

Performance Note

- ◆ Use pH-neutral cleaners, avoid acidic or solvent-heavy products.

- ◆ Maintain a simple wipe, rinse, dry routine.

- ◆ Schedule periodic inspections and follow care and cleaning guidance for long-term durability.

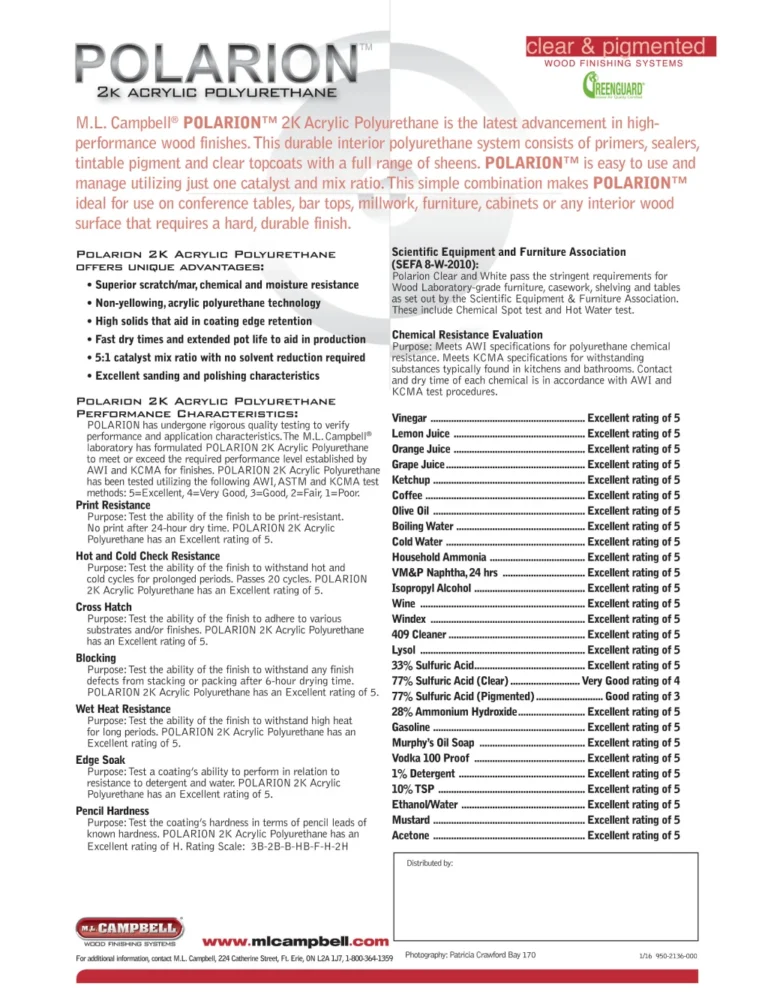

Film Finishes (Acrylic Polyurethane)

- First, it creates a tough, chemical-resistant barrier over the wood, so cleaning products, spills, and heat cannot penetrate, keeping surfaces smooth and non-sticky, even during harsh routines.

- Next, superior heat resistance is proven by our internal heat testing. These finishes protect against repeated exposure to hot plates and beverages without discoloration, warping, or residual stickiness.

- Additionally, it is highly durable and built for commercial use, ensuring long-term resilience in high-traffic environments.

- Finally, our acrylic polyurethane is SEFA-8 tested, a rigorous standard for chemical and stain resistance in commercial furniture, so you can be confident it stands up to the toughest restaurant cleaning regimens. To the right is a full list of the professional testing performed and the results.

The Problem with Lesser Finishes

Not all film finishes are created equal. Many commercial furniture makers use conversion varnish, precatalyzed lacquer, or lower-end catalyzed varnishes. While they may look good when new, they simply don’t hold up in restaurant conditions:

- Conversion varnish often begins to soften and get sticky under continuous cleaning. Depending on how aggressively the tables are cleaned and what products are used, breakdown typically occurs in 1–4 years.

- Lacquers and some water-based coatings break down even faster, showing wear within months in high-volume restaurants.

- Once these finishes degrade, no amount of cleaning removes the tacky feel, it’s a failure of the finish itself, not the cleaning staff.

This is why TimeWorn relies exclusively on industrial-grade acrylic polyurethane systems that outperform every other film finish available in terms of chemical resistance, heat tolerance, and long-term durability.

Non-Film Finishes (Penetrating Oils)

- Oils like Rubio and Seal-Once absorb into the wood, preserving a natural aesthetic with no film on top—great for spot repair but less protective against heavy-duty cleaning.

- Best for settings seeking a rustic or organic vibe and less aggressive cleaning routines, such as a residential environment.

Why Acrylic Polyurethane Is Our Go-To

- Through years of testing, it outperforms penetrating oils and all subpar film finishes in resisting chemicals, moisture, heat, and scratches—and crucially, maintains a non-sticky surface.

- It protects the wood so effectively that, even when heated beyond typical restaurant conditions, the wood remains beautiful and intact.

- With its SEFA-8 certification, it represents the highest industry standard for finish durability in restaurants.

Considerations for Your Specific Needs

- For indoor, high-use environments: Acrylic polyurethane delivers longevity, easy cleaning, and a consistently smooth, hygienic feel.

- For outdoor, rustic, or low-maintenance needs: Penetrating oils can offer a charming aesthetic, just expect easier spot repair but more susceptibility to UV damage as well as wear and tear.

Maintenance & Cleaning for Solid Wood Table Tops

Maintenance & Cleaning Guide

Well-planned care keeps restaurant table tops looking consistent and reduces downtime. Use approved neutral cleaners for daily wipe-downs, avoid abrasive pads and strong solvents, and protect surfaces from prolonged heat and standing liquids. Spot-clean spills quickly, dry the surface, and rotate two-tops/four-tops periodically to even out wear. Inspect edges and fasteners during routine cleaning; address loose hardware early and touch up minor scuffs before they become repairs. For long-term appearance, follow the finish manufacturer’s re-coat schedule and keep a small maintenance kit on hand. A simple, repeatable checklist extends service life, preserves brand standards, and keeps every table photo-ready from open to close.

Durability isn’t just about what you buy, it’s also about how you care for it. Every TimeWorn tabletop ships with a care sticker reminding your staff of best practices, because proper maintenance extends the life of your investment and reduces warranty claims. Displaying that same sticker image on your website is often the clearest way to get staff and managers on the same page.

Daily Care: Wipe with hot water and mild soap using a soft cloth or use approved disinfectant wipes such as Clorox® or Lysol® disinfectant wipes.

🚫 The Biggest Mistake: Flipping Chairs on Tables

One of the most damaging practices we see in restaurants is staff flipping chairs upside down onto tabletops when cleaning floors. No matter how durable our SEFA-8 tested acrylic polyurethane finish is, it cannot withstand the repeated impact of sharp-edged wood or metal chairs smashing against it.

The results are inevitable:

- Dents and gouges in the wood itself (not just the finish).

- Missing chunks along the edges where chair legs have cut into the surface.

- Premature failure of the finish in those damaged spots, exposing raw wood underneath.

The photos above show real-life examples of what happens when this practice continues over time.

⚠️ Avoid Harmful Cleaners:

- Do not use ammonia-based cleaners, degreasers, silicone polishes, or abrasive pads.

- Never use sulfuric or muriatic acid-based cleaners (shockingly common in back-of-house kitchens). These products will break down any finish, including our SEFA-8 tested acrylic polyurethane, and once damage begins, it cannot be reversed.

- In short: don’t make the second “biggest mistake” by using a back-of-house cleaner on the front-of-house tables.

Cost Factors & ROI

What Goes Into the Cost of Restaurant Tables

When planning your restaurant, it’s important to understand that the cost of tables is about much more than just “buying a piece of furniture.” The total price reflects the materials, craftsmanship, and finishing systems required to ensure your tables look beautiful, perform under daily stress, and stand the test of time.

Key Cost Factors:

- Wood Species: Premium hardwoods like walnut or quarter-sawn oak cost more than pine or ash, but they bring unique grain, color, and long-term durability.

- Construction Method: Solid wood vs. veneer, butcher block vs. classic style, and custom CNC shaping all affect both cost and performance.

- Finish System: Industrial-grade, SEFA-8 tested acrylic polyurethane finishes provide long-term protection but require significant labor and material investment compared to lacquers or oils.

- Customization: Logos, engraved designs, routed edges, waterfall ends, live-edge slabs, or matching expansions raise costs but elevate branding and guest experience.

- Size & Thickness: Larger, thicker tops use more lumber and require specialized handling, increasing both material and production costs.

- Hardware & Joinery: Commercial-grade brackets, fasteners, and expansion connectors ensure strength and longevity, but add to overall cost.

- Labor & Craftsmanship: Skilled milling, sanding, spraying, and quality control are labor-intensive but essential to producing a flawless product.

- Logistics: Shipping, crating, and safe delivery across the country contribute to total investment, especially for oversized bar tops or communal tables.

Cost Benefit

- ◆ SEFA-8 grade finishes resist heat and chemicals, reducing refinish events and downtime.

- ◆ Pre-drilling adds a small shop cost, often saving $40–$60 per base and ~20 minutes during install.

- ◆ Durable species and joinery extend service life, lowering replacement, freight, and reinstallation costs.

- ◆ Consistent fit and finish improve guest perception, supporting reviews and repeat visits over time.

Impact on Your Bottom Line:

The choices you make; species, finish, style, customization, and even color, will directly influence how long your tables last, how they look to guests, and how well they represent your brand. Beautiful, durable tabletops improve guest perception, reduce replacement costs, and help drive positive reviews. In short, the right tables are an investment that pays for itself in both longevity and reputation. Below is a chart with considerations before going with a lesser quality and likely, lesser cost up-front product.

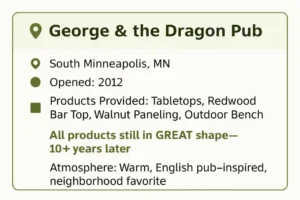

Case Study: George & the Dragon Pub, South Minneapolis

Overview

Since opening in 2012, George & the Dragon Pub has become a South Minneapolis landmark. Inspired by traditional English public houses, it blends pub classics with family recipes in a warm, neighborhood setting. Its owner, Fred Navarro, envisioned a space that felt authentic, sustainable, and built to last, and TimeWorn delivered exactly that.

TimeWorn’s Contribution

We provided nearly all the signature wood elements that define the pub’s atmosphere:

- Butcher-block Nutty Oak tabletops (now called Nutty Oak) – rich texture, warmth, and durability

- Reclaimed redwood bar top – wide, bold, and one-of-a-kind, salvaged from a century-old barn

- Walnut wall paneling & crown molding – refined detail elevating the space’s design

- Custom outdoor bench – built to last through Minnesota’s weather

“The one thing that sets TimeWorn apart … is the personal touch you get with Jared & Amanda. They care about the quality of the product, and they care about you as a customer. We’ve always viewed Jared & Amanda like family, and they treat George & the Dragon like it’s their restaurant.”

— Fred Navarro, Owner

Long-Term Durability

Every piece TimeWorn crafted for George & the Dragon is still in use today, more than a decade later, and in excellent condition. This proves that durability isn’t just a claim; it’s a long-term reality when you invest in premium materials, finishes, and craftsmanship.

Every piece TimeWorn crafted for George & the Dragon is still in use today, more than a decade later, and in excellent condition. This proves that durability isn’t just a claim; it’s a long-term reality when you invest in premium materials, finishes, and craftsmanship.

- Tables have survived over 10 years of daily service

- Finishes remain smooth and resilient against commercial cleaning

- Reclaimed materials tell a story while holding up under constant use

Why it Matters

- George & the Dragon demonstrates how the right tables and finishes are not just décor, they’re part of the experience. Every guest interaction, every plate served, and every drink poured happens on surfaces that remain beautiful, durable, and true to the restaurant’s story.

- This is the value of investing in TimeWorn: craftsmanship that doesn’t just open strong but continues to perform, year after year.

How to Order Restaurant Tabletops

Ready to elevate your space with TimeWorn’s handcrafted tabletops? Here’s the streamlined process from start to finish:

1. Initial Consultation

Start by reaching out via email or phone. Be ready to share your restaurant’s name, address, zip code (for shipping), desired tabletop styles (Classic, Butcher Block, Distressed, etc.), quantities, sizes, and your installation timeline. The more info we have upfront, the smoother and faster the process.

2. Samples & Quote

We’ll send you a detailed quote and a full-size 12″ × 12″ sample that represents the exact finish and thickness of your final product. Test it; place a hot dish, pour some wine, or wipe it with your cleaning methods to confirm it meets your expectations.

3. Contract & Down Payment

Once you’re ready to proceed, we’ll send a contract. Your order enters production once the signed contract and down payment are received. Remember, quoted lead times (e.g., 6 weeks) start only after this step.

4. Production

Your tabletops are meticulously crafted using solid wood, with moisture content at 6% or lower to prevent warping, cupping, or cracking, especially for quarter-sawn planks.

Once production starts, selections like sizes or finishes can’t be changed, so review your order carefully before approval.

5. Shipping

We coordinate delivery to your specified location. Given the size and weight of tabletops, shipping costs can rival the price of smaller orders, so confirming your order details beforehand ensures efficiency and avoids costly revisions.

6. Installation

Install your new TimeWorn tabletops and turn your vision into reality.

Installation Reminder

Always ask us to pre-drill your tabletops before shipment. Spending a few hundred dollars during production can save thousands in on-site labor. Confirm your base footprint, pilot-hole size, and screw length to ensure fasteners never penetrate the finished surface. Once installed, level all bases, apply threadlocker on bolts, and recheck connections after the first week of service. For ongoing upkeep, review our care and cleaning guidelines.

7. Share Your Results

We love seeing your space in action. Send us photos and feedback once your tables are installed so we can share your project with others.